The development of advanced electrode materials for high-performance sodium-ion batteries (SIBs) has drawn considerable attention in recent years. These materials play a critical role in the performance and efficiency of SIBs, which are emerging as promising alternatives to lithium-ion batteries (LIBs) for large-scale energy storage applications due to their low cost, high abundance, and environmental sustainability.

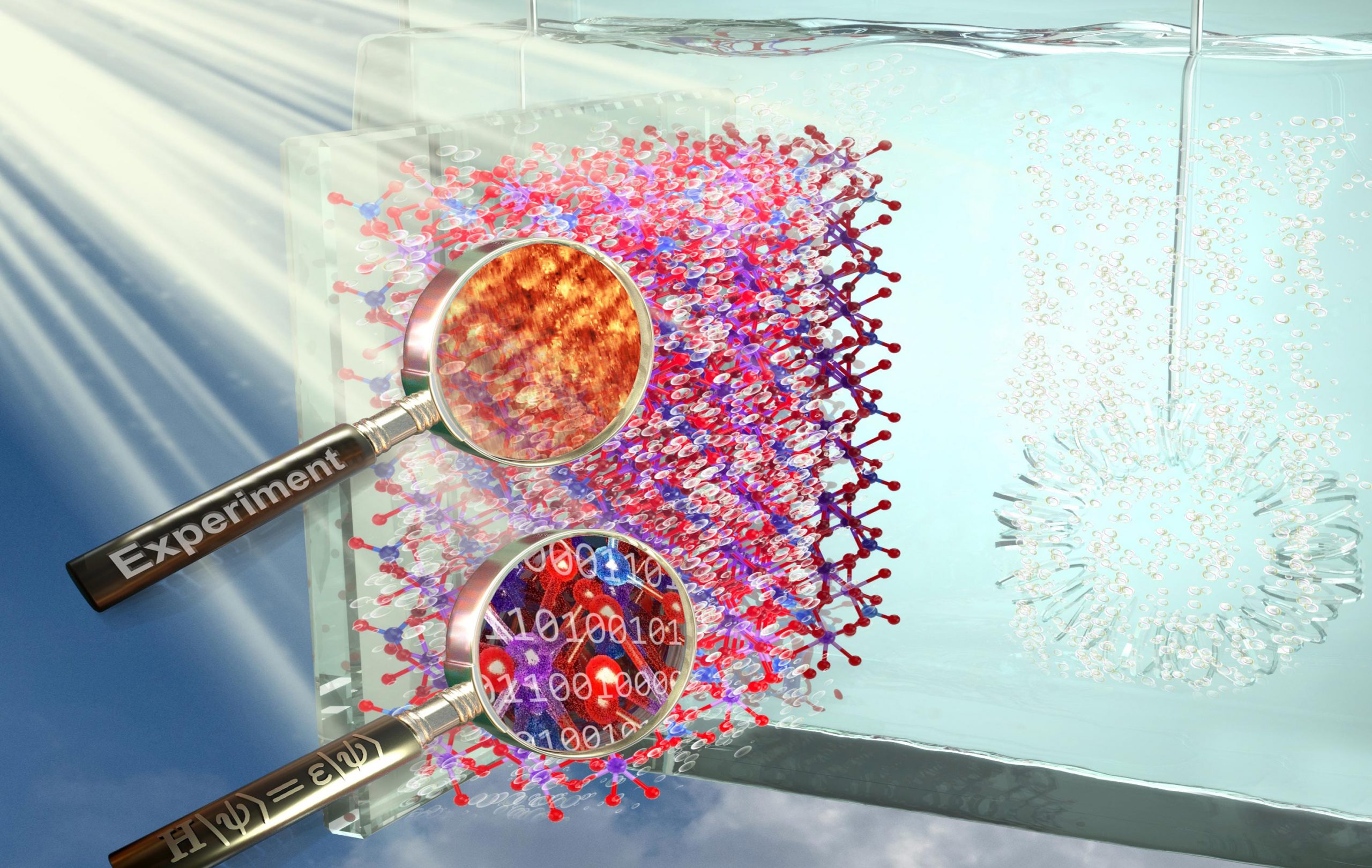

One of the major challenges in SIBs is the limited choice of electrode materials compared to LIBs. This is because the insertion and extraction of sodium ions in these materials require larger ion sizes and lower redox potentials than that of lithium ions. Therefore, designing suitable electrode materials for SIBs requires a careful consideration of their crystal structure, electronic conductivity, and ionic diffusion properties.

In recent years, extensive research efforts have led to the discovery of a variety of electrode materials that show promising performance for SIBs. These materials can be broadly classified into two categories: intercalation-type and conversion-type materials.

Intercalation-type materials involve the reversible insertion and extraction of sodium ions into the interstitial sites of the host material's crystal structure. These materials typically exhibit high capacity, low voltage profile, and excellent cycling stability. Common examples of intercalation-type electrode materials include sodium-based layered oxides, tunnel structured materials, and phosphate-based materials.

Conversion-type materials, on the other hand, involve the reversible conversion of the electrode material's chemical composition during charge and discharge cycles. These materials typically exhibit higher capacity and energy density than intercalation-type materials, but suffer from poor cycling stability and voltage hysteresis. Common examples of conversion-type materials include metal sulfides, metal oxides, and metal fluorides.

In addition to the choice of electrode material, the design of the electrode structure is also critical for the performance of SIBs. One recent development in this field is the use of high performance concrete as a binder material for SIB electrodes.

High performance concrete is a type of concrete that has superior strength, durability, and resistance to environmental degradation compared to conventional concrete. It is produced using high-quality cement, aggregates, and admixtures, and is designed to meet specific performance requirements.

In the context of SIB electrode materials, high performance concrete can serve as a binder material that provides mechanical stability, electrical conductivity, and chemical stability to the electrode structure. This can improve the performance and cycling stability of SIBs by preventing electrode degradation, increasing the electrode-electrolyte interface area, and facilitating ion transport.

Several studies have demonstrated the potential of high performance concrete as a binder for SIB electrodes. For example, a recent study reported the successful incorporation of high performance concrete into an SIB electrode based on a carbon nanofiber/sodium titanate nanotube composite. The resulting electrode showed improved structural stability, cycling stability, and rate capability compared to conventional epoxy-based binders.

In conclusion, the development of advanced electrode materials is critical for the performance and efficiency of SIBs. Intercalation-type and conversion-type materials are promising candidates for SIB electrodes, and ongoing research efforts are focused on improving their performance and stability. The use of high performance concrete as a binder material is a recent development that shows promise for improving the performance and cycling stability of SIB electrodes. These advancements have paved the way for the widespread adoption of SIBs in large-scale energy storage applications.